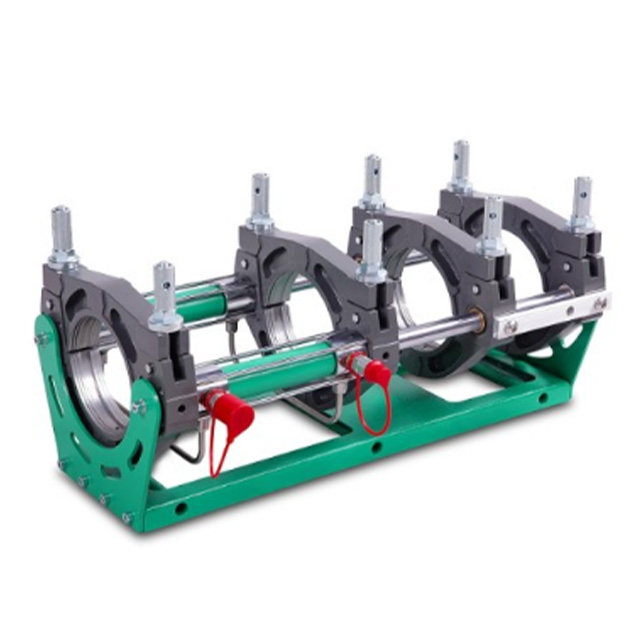

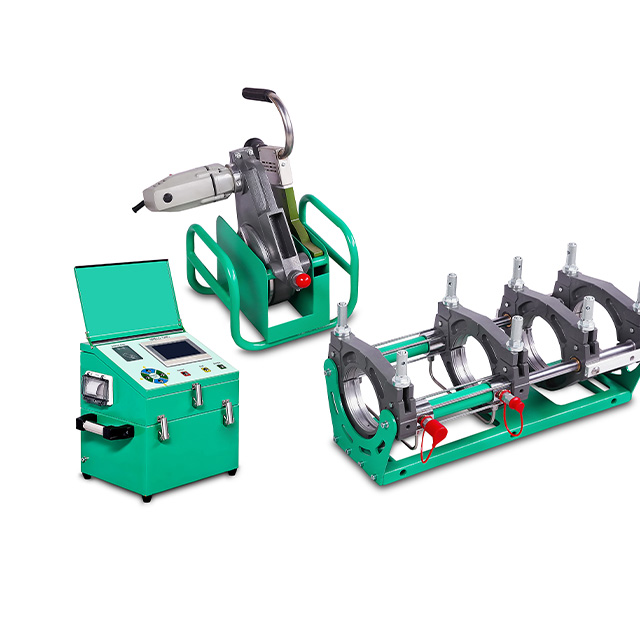

HDPE Butt Fusion Machine SWT-V450/200D

Welding ranges:200mm-450mm (8''-18''inch)

(200mm-225mm-250mm-280mm-315mm-355mm-400mm-450mm)

Application: PE,PP and PVDF

Working voltage:380V ±10%,50Hz

Total power: 8.2 KW,including:planning tool:1.5 KW, heating plate:5.2 KW, hydraulic unit:1.5KW

PTFE coated heating plate, adjustable knob for temperature control, difference in heating plate surface temperature ≤±7°.

Environment temperature: -10° - 45°

Electronic count-down timer for heating and cooling time.

Whole machine consists of basic frame, heating plate, planning tool, hydraulic unit and

support (for planning tool & heating plate)

SWT-V450/200D HDPE Pipe Welding Machine

Application

Suitable for butt welding of plastic pipes and fittings made of PE,PP, and PVDF in worksite or workshop.

Features

Removable PTFE coated heating plate with separate temperature control system.

Electrical planning tool;

Be made of lightweight and high strength material; simple structure, small and delicate user friendly;

Low starting pressure ensures reliable welding quality of small pipes;

Separate two-channel timer shows time in soaking and cooling phases;

High-accurate and shockproof pressure meter in indicates clear readings.

Technical specifications

Welding ranges:200mm-450mm (8''-18''inch)

(200mm-225mm-250mm-280mm-315mm-355mm-400mm-450mm)

Application: PE,PP and PVDF

Working voltage:380V ±10%,50Hz

Total power: 8.2 KW,including:planning tool:1.5 KW, heating plate:5.2 KW, hydraulic unit:1.5KW

PTFE coated heating plate, adjustable knob for temperature control, difference in heating plate surface temperature ≤±7°.

Environment temperature: -10° - 45°

Electronic count-down timer for heating and cooling time.

Whole machine consists of basic frame, heating plate, planning tool, hydraulic unit and

support (for planning tool & heating plate)

Optional:

Automatic“jumping” heating element & milling cutter;

Wheeled trolley available;

Flange stub;

Narrow clamps;

Single clamps;

Data logger;

Crane(lifter)

Closed Hydraulic unit systems.

All designed according to ISO21307:2011(E),ISO12176-1 and DVS2207/1(08/2007)

International warranty: 24months.

Any parts broken or does not work under normal operating,we are free to provide.

HDPE Butt Fusion Machine SWT-V450/200D